Quality and Reliability

Leading Quality for Customer SuccessQuality Policy

Leading Quality for Customer Success

Providing Optimum Quality to Customers through Comprehensive Management Systems.

The products of Socionext are utilized in various fields and are playing very important roles in our customers’ products. We build quality products that meet the varying QCD (Quality, Cost, and Delivery) needs of our customers. Additionally, through comprehensive management systems for the planning and design stages, we as a fabless company choose perfect partner companies (contract manufacturers) in Japan and overseas according to the characteristics, functionality, and quality of products to be manufactured. Moreover, by leveraging our high-quality and reliable technology that has been developed in the global market and through strong cooperation with our partner companies (contract manufacturers), we provide optimum quality to our customers in a timely manner.

Honing from the Source(Design Review)

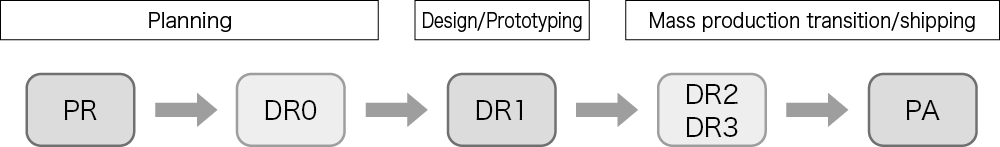

Each step at the development process, such as market, research, product planning and development planning is completed with design review before starting mass production. In our quality assurance program, design review consists of six steps: product planning validity review (PR), product development plan review (DR0), product design validity review (DR1), mass production transition validity review (DR2), mass production start review (DR3), and pre-shipment audit (PA). We place particular emphasis on the product planning validity review (PR) and product development plan review (DR0). By identifying problems at an earlier stage, we are able to resolve issues to hone quality from the source. Also, we optimize our review contents to ensure that nothing is left out.

| Name | Role | Description |

|---|---|---|

| PR |

Product planning validity review |

We consider the target quality and target reliability to be used for the new product and confirm product development with the agreement of all related offices. |

| DR0 |

Product development plan review |

We clarify the resources and work required to develop the new product and establish a plan that accounts for everything. |

| DR1 |

Product design validity review |

Completing the planned design work, we check that the basic design matches the customer's requirements. |

| DR2 | Mass production transition validity review | We confirm the necessary specifications for mass production prototyping, based on results obtained from prototype evaluation. |

| DR3 |

Mass production start review |

We use the mass production prototype to evaluate the characteristics of the product and confirm the necessary specifications and facilities for mass production. |

| PA | Pre-shipment review | We conduct feedback based on initial flow management results and in-process fault information. |

ISO9001 Certification

ISO9001 is an international standard for quality management systems with the aim of improving product quality assurance systems and increasing customer satisfaction. We acquired ISO9001 certification.

Furthermore, we have set up a system that can expand globally using the production lines of partner companies that have the IATF16949 certification, which is standard in the automotive industry.